Page 73 - 20250602 EEA QM Edition 6.0

P. 73

Quality Requirements Edition 6.0 European Enamel Association

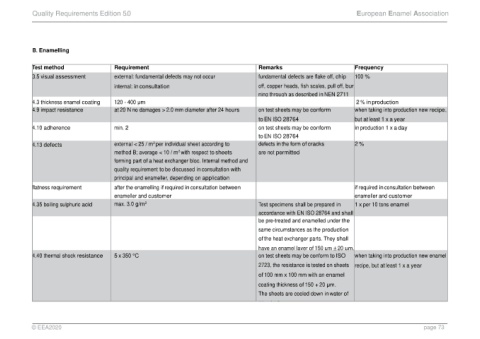

B. Enamelling

Test method Requirement Remarks Frequency

3.5 visual assessment external: fundamental defects may not occur fundamental defects are flake off, chip off, 100 %

internal: in consultation copper heads, fish scales, pull off, burning

through as described in NEN 2711

4.3 thickness enamel coating 120 - 400μm 2 % in production

4.9 impact resistance at 20 N no damages > 2.0 mm diameter after 24 hours on test sheets, conform to EN ISO 28764 when taking into production new

recipe, but at least 1 x a year

4.10 adherence min. 2 on test sheets, conform to EN ISO 28764 in production 1 x a day

2

4.13 defects external < 25 / m per individual sheet according to defects in the form of cracks are not permitted 2 %

method B; average < 10 / m with respect to sheets

2

forming part of a heat exchanger bloc. Internal method

and quality requirement to be discussed in consultation

with principal and enameller, depending on application

flatness requirement after the enamelling if required in consultation between if required in consultation between

enameller and customer enameller and customer

4.35 boiling sulphuric acid max. 3.0 g/m Test specimens shall be prepared in 1 x per 10 tons enamel

2

accordance with EN ISO 28764 and shall be

pre-treated and enamelled under the same

circumstances as the production of the heat

exchanger parts. They shall have an enamel

layer of 150μm ± 20μm.

4.40 thermal shock resistance 5 x 350 °C on test sheets conform to EN ISO 2723 when taking into production new

enamel recipe, but at least 1 x a year

the resistance is tested on sheets of 100 mm

x 100 mm with an enamel coating thickness

of 150μm ± 20μm.

The sheets are cooled down in water at 20°C

© EEA2025 page 73