Page 68 - 20250602 EEA QM Edition 6.0

P. 68

Quality Requirements Edition 6.0 European Enamel Association

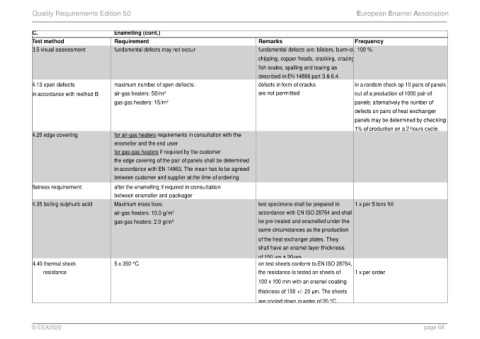

C. Enamelling (cont.)

Test method Requirement Remarks Frequency

3.5 visual assessment fundamental defects may not occur fundamental defects are: blisters, burn- 100 %

off, chipping, copper heads, cracking,

crazing fish scales, spalling and tearing

as described in EN ISO 28763 part 6.4.

4.13 open defects maximum number of open defects: defects in form of cracks are not in a random check op 10 pairs of

in accordance with method B air-gas heaters: 50/m permitted panels out of a production of 1000 pairs

2

2

gas-gas heaters: 15/m of panels; alternatively, the number of

defects on pairs of heat exchanger

panels may be determined by checking

1% of production on a 2 hours cycle.

4.20 edge covering for air-gas heaters requirements in consultation with the

enameller and the end user

for gas-gas heaters if required by the customer

the edge covering of the pair of panels shall be determined

in accordance with EN 14863. The mean has to be agreed

between customer and supplier at the time of ordering

flatness requirement after the enamelling if required in consultation

between enameller and packager

4.35 boiling sulphuric acid Maximum mass loss: test specimens shall be prepared in 1 x per 5 tons frits

2

air-gas heaters: 10.0 g/m accordance with EN ISO 28764 and shall

gas-gas heaters: 2.0 g/m be pre-treated and enamelled under the

2

same circumstances as the production

of the heat exchanger plates. They

shall have an enamel layer thickness

of 150μm ± 20μm.

4.40 thermal shock 5 x 350 °C on test sheets conform to EN ISO 28764, 1 x per order

resistance the resistance is tested on sheets of 100

x 100 mm with an enamel coating

thickness of 150μm +/- 20μm.

The sheets are cooled down in water at

20 °C

© EEA2025 page 68