Page 78 - 20250602 EEA QM Edition 6.0

P. 78

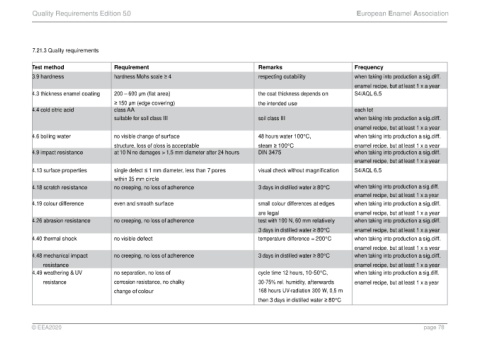

Quality Requirements Edition 6.0 European Enamel Association

7.20.4 Remarks

Colour and colour tolerances of the outside surface shall be agreed between interested parties. Inspection frequency to be determined according EN ISO 2859-1. Inspection

method to be approved prior to production.

Consult with supplier for suitability for specific applications. All applications subject to concentration and temperature considerations of the stored liquid.

© EEA2025 page 78