Page 74 - 20250602 EEA QM Edition 6.0

P. 74

Quality Requirements Edition 6.0 European Enamel Association

st

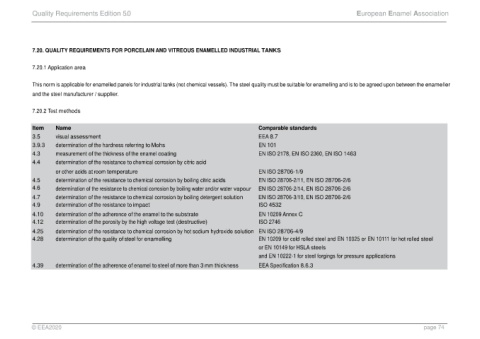

7.20. QUALITY REQUIREMENTS FOR PORCELAIN AND VITREOUS ENAMELLED INDUSTRIAL TANKS – 1 GROUP

7.20.1 Application area

These requirements are applicable for enamelled panels for bolted steel tanks for the storage or treatment of water or municipal or industrial effluents and sludges (not chemical

vessels). This section (7.20) refers exclusively to the tanks dedicated to the below listed applications:

- Industrial effluent process/treatment including aggressive chemical industrial effluent /high temperature applications

- Industrial tanks with aeration processes

- Roofs exposed to gaseous zone in biogas digester for agricultural waste (not the cylinders, see section 7.21)

- Cylinders and roofs of thermophilic/pasteurisation digesters

- Roofs exposed to gaseous zone in municipal mesophilic digesters (not the cylinders, see section 7.21)

- Liquid leachate

- Roofs exposed to gaseous zone in municipal sludge treatment (not the cylinders, see section 7.21)

- Borehole / brackish / sea water

nd

See also for other application areas the section 7.21 QUALITY REQUIREMENTS FOR PORCELAIN AND VITREOUS ENAMELLED INDUSTRIAL TANKS – 2 GROUP

7.20.2 Test methods

Item Name Applicable standards

3.5 visual assessment EEA 8.7

3.9.3 determination of the hardness referring to Mohs EN ISO 6769

4.3 measurement of the thickness of the enamel coating EN ISO 2178, EN ISO 2360, EN ISO 1463

4.4 determination of the resistance to chemical corrosion by EN ISO 28706-1/9, EN ISO 28706-1/10, EN ISO 28706-1/11

acids at room temperature

4.5 determination of the resistance to chemical corrosion by boiling citric acids EN ISO 28706-2/11

4.6 determination of the resistance to chemical corrosion by boiling water and/or water EN ISO 28706-2/14

vapour

4.7 determination of the resistance to chemical corrosion by standard detergent solution EN ISO 28706-3/10

© EEA2025 page 74