Page 66 - 20250602 EEA QM Edition 6.0

P. 66

Quality Requirements Edition 6.0 European Enamel Association

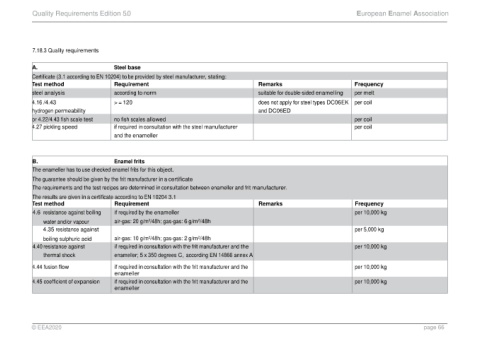

7.18.3 Quality requirements

A. Steel base

Certificate (3.1 according to EN 10204) to be provided by steel manufacturer, stating:

Test method Requirement Remarks Frequency

steel analysis according to norm suitable for double-sided enamelling per melt

4.16 /4.43 > = 120 does not apply for steel types DC06EK per coil

hydrogen permeability / DC06ED and DC07EK

or 4.22/4.43 fish scale test no fish scales allowed per coil

4.27 pickling speed if required in consultation with the steel manufacturer per coil

and the enameller

B. Enamel frits

The enameller has to use checked enamel frits for this object

The guarantee should be given by the frit manufacturer in a certificate

The requirements and the test recipes are determined in consultation between enameller and frit manufacturer

The results are given in a certificate according to EN 10204 3.1

Test method Requirement Remarks Frequency

4.6 resistance against boiling if required by the enameller per 10,000 kg

2

2

water and/or vapour air-gas: 20 g/m /48h; gas-gas: 6 g/m /48h

4.35 resistance against per 5,000 kg

boiling sulphuric acid air-gas: 10 g/m /48h; gas-gas: 2 g/m /48h

2

2

4.40 resistance against if required in consultation with the frit manufacturer and the per 10,000 kg

thermal shock enameller; 5 x 350 degrees C, according EN ISO 28763

annex A

4.44 fusion flow if required in consultation with the frit manufacturer and the per 10,000 kg

enameller

4.45 coefficient of expansion if required in consultation with the frit manufacturer and the per 10,000 kg

enameller

© EEA2025 page 66