Page 62 - 20250602 EEA QM Edition 6.0

P. 62

Quality Requirements Edition 6.0 European Enamel Association

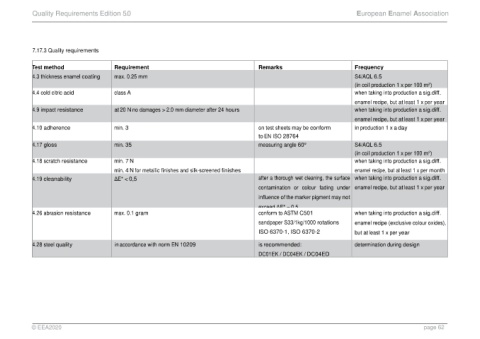

7.17.3 Quality requirements

Test method Requirement Remarks Frequency

4.3 thickness enamel coating max. 0.25 mm S4/AQL 6.5

(in coil production 1 x per 100 m )

2

4.4 cold citric acid class A when taking into production a sig.diff.

enamel recipe, but at least 1 x per year

4.9 impact resistance at 20 N no damages > 2.0 mm diameter after 24 hours when taking into production a sig.diff.

enamel recipe, but at least 1 x per year

4.10 adherence min. 3 on test sheets, conform to EN ISO 28764 in production 1 x a day

4.17 gloss min. 35 measuring angle 60° S4/AQL 6.5

2

(in coil production 1 x per 100 m )

4.18 scratch resistance min. 7 N when taking into production a sig.diff.

min. 4 N for metallic finishes and silk-screened finishes enamel recipe, but at least 1 x per month

4.19 colour difference after ΔE* < 0,5 after a thorough wet cleaning, the surface when taking into production a sig.diff.

cleaning contamination or colour fading under enamel recipe, but at least 1 x per year

influence of the marker pigment should not

exceed ΔE* = 0,5.

4.26 abrasion resistance max. 0.1 gram conform to ASTM C501 when taking into production a sig.diff.

sandpaper S33/1kg/1000 rotations EN enamel recipe (excluding colour oxides),

ISO 6370-1 and 6370-2 but at least 1 x per year

4.28 steel quality in accordance with norm EN 10209 is recommended: determination during design

DC01EK / DC04EK / DC04ED

© EEA2025 page 62