Page 67 - 20250602 EEA QM Edition 6.0

P. 67

Quality Requirements Edition 6.0 European Enamel Association

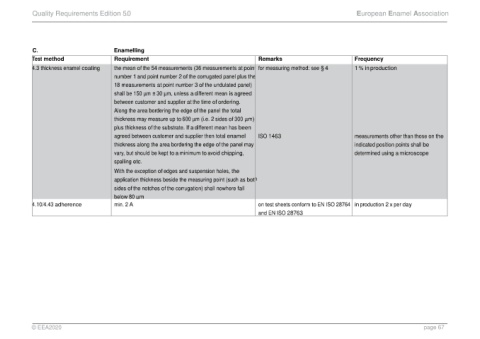

C. Enamelling

Test method Requirement Remarks Frequency

4.3 thickness enamel coating the mean of the 54 measurements (36 measurements at point for measuring method: see § 4 1 % in production

number 1 and point number 2 of the corrugated panel plus the

18 measurements at point number 3 of the undulated panel)

shall be 150 µm ± 30 µm, unless a different mean is agreed

between customer and supplier at the time of ordering.

Along the area bordering the edge of the panel the total

thickness may measure up to 600 µm (i.e. 2 sides of 300 µm)

plus thickness of the substrate.

If a different mean has been agreed between customer and

supplier then total enamel thickness along the area bordering EN ISO 1463 measurements other than those on the

the edge of the panel may vary, but should be kept to a indicated position points shall be

minimum to avoid chipping, spalling etc. determined using a microscope

With the exception of edges and suspension holes, the

application thickness beside the measuring point (such as both

sides of the notches of the corrugation) shall nowhere fall

below 80 µm

4.10/4.43 adherence min. 2 A on test sheets conform to EN ISO in production 2 x per day

28764 and EN ISO 28763

© EEA2025 page 67