Page 61 - 20250602 EEA QM Edition 6.0

P. 61

Quality Requirements Edition 6.0 European Enamel Association

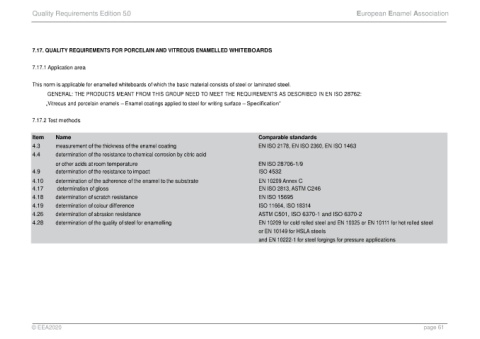

7.17. QUALITY REQUIREMENTS FOR PORCELAIN AND VITREOUS ENAMELLED WHITEBOARDS

7.17.1 Application area

These requirements are applicable for enamelled whiteboards of which the basic material consists of steel or laminated steel.

GENERAL: THE PRODUCTS MEANT FROM THIS GROUP NEED TO MEET THE REQUIREMENTS AS DESCRIBED IN EN ISO 28762:

“Vitreous and porcelain enamels – Enamel coatings applied to steel for writing surface – Specification”

7.17.2 Test methods

Item Name Applicable standards

4.3 measurement of the thickness of the enamel coating EN ISO 2178, EN ISO 2360, EN ISO 1463

4.4 determination of the resistance to chemical corrosion by citric acid EN ISO 28706-1/9

or other acids at room temperature

4.9 determination of the resistance to impact EN ISO 4532

4.10 determination of the adherence of the enamel to the substrate EN 10209 Annex C

4.17 determination of gloss EN ISO 2813, ASTM C246

4.18 determination of scratch resistance EN ISO 15695

4.19 determination of colour difference EN ISO/CIE 11664, EN ISO 18314

4.26 determination of abrasion resistance ASTM C501, EN ISO 6370-1and 6370-2

4.28 determination of the quality of steel for enamelling EN 10209 for cold rolled steel and see 4.28 recommendations for hot rolled steels,

HSLA steels and steel forgings for pressure applications

© EEA2025 page 61