Page 126 - 20250602 EEA QM Edition 6.0

P. 126

Quality Requirements Edition 6.0 European Enamel Association

8.7.3 Valuation of cracks in enamellings The formation of cracks, as a result of a too long and unreasonable influence of high

temperature, (e.g. more than 530 C) often displays a metallic luster as a result of the

0

Definition and cause diffusion of metal oxide.

Following the definition of DIN 50903: Cracks are mostly laminar interruptions in

enamel- lings. They often run vertical to the surface, but occur also under different To be mentioned in the test report:

angles. Their causes are mainly mechanical - or thermal tensions in the compound kind and origin of the test piece

system. place and date of the testing

Under thermal shocks, tensile stresses are built up due to different expansion description of defects, number and extent

behaviours of the metal substrate and the enamel to which an enamelling is less

resistant as to compressive stresses. Unreasonable deformations or impact stresses

on finished enamellings set off cracks.

Consideration and description

The judgement of damage by cracks is performed by naked eye.

One differentiates between:

a. open, piercing cracks

b. open, non-piercing cracks

c. masked cracks

Open, piercing cracks are interruptions in the enamel layer down to the metal

substrate. They can be made visible clearly by physical (e.g. electrostatic) or

chemical methods. Open, non-piercing cracks cease in the enamel layer. They

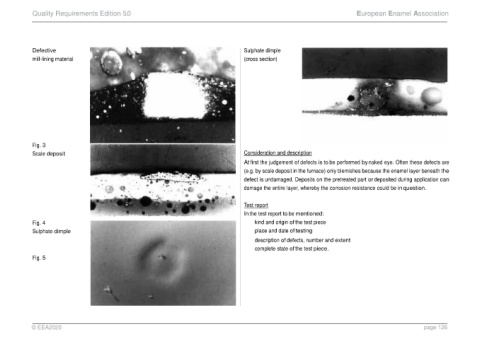

Illustration: Formation of cracks in an enamel layer (enlargement 200 : 1)

cannot be made visible by such method, as there is no prerequisite reaction with the

metal substrate. Wet or dry pigments are rubbed into the enamel surface, in order to

recognize such crack formation. These pigments concentrate on the edges of cracks,

by which they clearly indicate the crack propagation.

Masked (inner) cracks glimmer in the enamel layer like mother-of-pearl, dependent

on the lighting equipment and lighting angle.

© EEA2025 page 126