Page 124 - 20250602 EEA QM Edition 6.0

P. 124

Quality Requirements Edition 6.0 European Enamel Association

The defect frequency will be reduced down to a minimum by a neat operation in good

8.7 Valuation of enamelling defects

controlled plants, and utilisation of defined and checked base materials.

8.7.1 General hints

For the optical surface quality, real and to the functional purpose of the workpiece

Definition

adjusted control standards are in particular an important criterion. Relating to this, a too

Defects in the enamelling are locally limited interruptions of the compactness severe standard reduces in general the entire product quality. The susceptibility to

or structure of the glasslike coating. The local penetration of one layer by another is mechanical damage (chipping, cracks) increases with the rise of enamel thickness.

likewise to be seen as a defect on multilayer enamellings, as in this case it is also a With each rework operation, the application thickness increases inevitably. To secure

structural interruption. Structural interruptions are not always visible by naked eye. the corrosion resistance on difficult accessible areas of articles with a high corrosion

Physical or chemical analyses may be used for the detection of defects. demand, special testing methods can be helpful (e.g. measurement of the protective

current requirement on enamelled hot water tanks).

By judging the defects, one should consider, whether thereby a diminution of function

of the article or merely an optical detraction arises. The optical Valuation is If by agreement with a client of certain articles, a certain number of defects (pores) is

independent of the functional application. not to be infringed, porosity tests complying to the defined standards EN ISO 2746

(high voltage) respectively to EN ISO 8289, NEN 2709 (sponge test with low voltage)

Typical enamelling defects are: have to be carried out. Note: High voltage can cause open defects (pores) from big

Burn off (EEA 8.7.2) blisters.

Cracks (EEA 8.7.3)

Pores and Inclusions (EEA 8.7.4)

Chipping, Spalling (EEA 8.7.5)

Contamination, fallen-on (EEA 8.7.6)

(all production areas)

Black Specks in the enamelling (EEA 8.7.7)

The common characteristic of enamellings is the melting together of siliceous (glass-

0

like) and metallic components in a temperature range of 500 - 950 C. By this,

reactions with the formation of gasses occur (mainly H2, CO and CO2). Detrimental

secondary effects can be suppressed but never entirely eliminated. Within an

industrial process, contaminations, also from different production lines are never

entirely avoidable - their effects intensify by the reaction with the molten enamel at

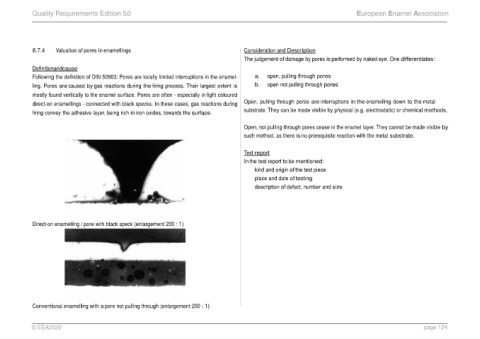

elevated temperature. A certain part of defects is therefore on enamellings Illustration: Big blister in an enamel layer. Its thin glass-skin can be disturbed by the

unavoidable. high voltage test. (enlargement 200 : 1)

© EEA2025 page 124