Page 122 - 20250602 EEA QM Edition 6.0

P. 122

Quality Requirements Edition 6.0 European Enamel Association

8.6.6. Admissible differences of application thickness on corrugated and Consideration

undulated pairs of sheet steel panels for heat exchanger The mean out of the 36 measurements on points No. 1 and 2 of the corrugated panel

must be < 250μm. A peak thickness on these points of < 300μm is permissible, but only

Purpose and scope one measurement, out of the 36, can be 20% above the maximum value. The average

Enamelled heat exchanger panels are exposed to mechanical and chemical demand. thickness on the 18 measuring points No. 3 of the undulated panel must be < 200μm.

In both cases, the application thickness of the protecting enamel layer is of decisive The maximum thickness is < 250μm, merely one measurement can be as high as

importance. Due to the nature of these parts, an absolutely even application is not 300μm. With the exception of edges and suspension holes, the application thickness

possible. Hence, this specification sheet tries to plot the requirements for admissible should nowhere fall below 80μm.

tolerances. On the edge area the entire thickness of the panel may measure 750μm + thickness of

the sheet.

Test method

Use a thickness measuring instrument of an accuracy of 0.01 mm. Measurements

are to be carried out from point A to I on the front and reverse side of the panel,

according to the sketch represented at the bottom. The test points are situated about

50 mm off the edge. The measuring points on the corrugated panel are marked with

No. 1 and 2, on the undulated panel with No. 3. Per pair of panels (one corrugated

and one undulated) 54 measurements (36+18) result from this test.

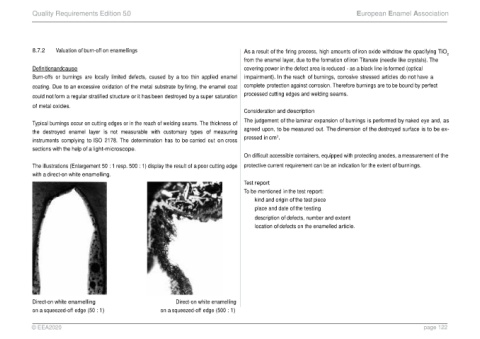

Illustration: Optical layer distribution on undulated sheet steel (enlargement 6 : 1)

© EEA2025 page 122