Page 128 - 20250602 EEA QM Edition 6.0

P. 128

Quality Requirements Edition 6.0 European Enamel Association

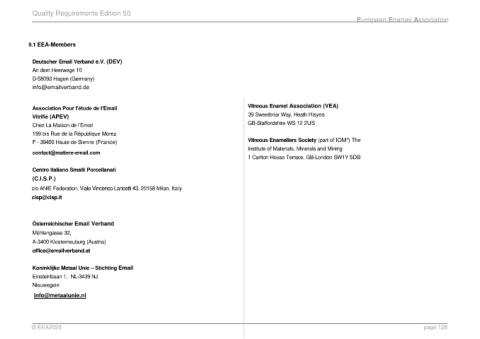

8.7.5 Valuation of chipping / spalling on enamellings 8.7.6 Valuation of defects as can be caused by deposits of impurities from

different production lines

Definition and cause

Definition and cause

Chipping or spalling on enamellings are mechanical destructions caused by cold

deformation, impact or inner stresses being self-caused within the composite In almost every manufacturing process of the enamelling shop (Raw manufacturing-

material. Chipping or spalling on cutting edges is mostly leading back to an imperfect Metal pretreatment - Milling - Application - Drying - Firing) there are characteristic

cutting operation or to a too heavy application of enamel. On principle the cause of deposits of impurities. Inclusions in the enamelling arise in dependence of the

chipping is, as far as possible, to be cleared on the spot. contaminating process: Defects from a defective mill-lining (Fig. 1 and 2) or superficially

molten-on deposit: Scale, deposited in the furnace (Fig. 3)

Consideration and description

If sulphuric acid is used in a pickling plant sulphates can be transported (e.g. by hangers

The judgement of damage is performed be naked eye. The description has, among

or via air streams) to the firing area. Deposited spots leave characteristic dimples

other things, also to assess the reverse side of the damaged part.

behind because of a decrease of the surface tension.

(Fig. 4 and 5)

Test report

To be mentioned in the test report:

kind and origin of test piece Fig. 1

place and date of testing Defective mill-iron shaving

description of defect, number and extent

complete state of the article

© EEA2025 page 128