Page 118 - 20250602 EEA QM Edition 6.0

P. 118

Quality Requirements Edition 6.0 European Enamel Association

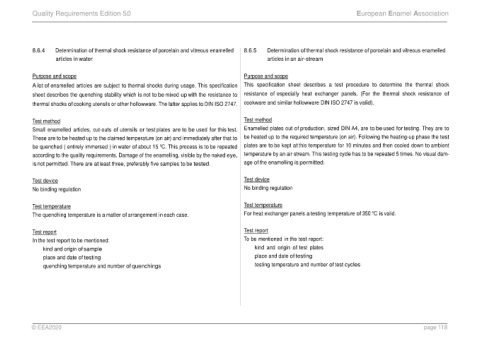

8.6 Testing of porcelain and vitreous enamel coatings 29. to 33. day daily water-replacement (5 week)

th

34. and 35. day no water-replacement

8.6.1 Determination of resistance to boiling water by long-term exposure 36. to 40. day daily water-replacement (6 week)

th

41. and 42. day day no water-replacement

Purpose and scope

43. day The test plates are, cleaned, dried and weighed.

The vitreous enamel coating of devices and receptacles, that have to face repetition

of stress by means of boiling or hot water, is tested for its resistance by a long-term Testing-device

exposure. Because of the high expenditure of time that is necessary for the test -

Apparatus according to EN ISO 28706-2/6

especially for hot water tanks - a suitable testing method must be followed.

Testing-time

Method of testing If no further arrangements have been made, a testing-time of 2 x 3 weeks is valid; the

The tests will be made according to EN ISO 28706-2 and the DIN 4753. The testing second testing round is rated.

time is set for 6 weeks. The tested plate is installed at the bottom of the apparatus

while the top plate (vapour phase) is a glass-plate (borosilicate glass 3.3 according Testing-temperature

to DIN ISO 3585). The test solution is demineralised water with a conductivity of max. If no further arrangements have been made, the test is realised at boiling temperature

1 μS/cm and renewed according to the following scheme: using a condenser and graduated collector such as described in EN ISO 28706-2/6 and

following procedure EN ISO 28706-2/8 for its usage.

1. to 5. day daily water-replacement (1 week)

st

6. and 7. day no water-replacement Test plates

8. to 12. day daily water-replacement (2 week)

nd

13. and 14. day no water-replacement The test plates should be made out of the same steel as the to be tested receptacle.

15. to 19. day daily water-replacement (3 week) Because of the weighing accuracy, the plates should not be thicker than 2 mm. The

rd

20. and 21. day no water-replacement enamelling should be of a thickness of at least 0.25 mm and its surface should be free

th

22. day The test plates are removed out of the (4 week) of weak or defective spots.

device and are cleaned and weighed.

After the weighing, the test plates are put The test plates can be produced either in the laboratory or in the enamel shop. In the

in the device again. last case, the test plates should be hooked on a stainless-steel hook and should be

The second testing round starts just like fired in the interior of a receptacle of the production. Using this method, the sample

the first day enamelling gains the same thermal treatment experience as the receptacle-enamelling.

23. to 26. day daily water-replacement (4 week tbc) Three test plates have to be tested. The average weight loss should not be higher than

th

2

27. and 28. day no water-replacement 12 g/m .

© EEA2025 page 118