Page 88 - 20250602 EEA QM Edition 6.0

P. 88

Quality Requirements Edition 6.0 European Enamel Association

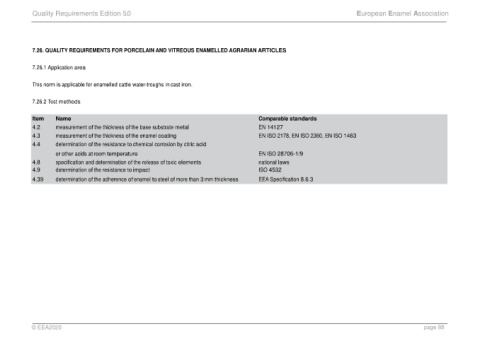

7.24.3 Quality requirements

Test method Requirement Remarks Frequency

3.9.5.3 cast iron quality EEA-specification 8.1 when taking into production

4.3 thickness enamel coating < 1.5 mm 1%

4.4 cold citric acid class AA when taking into production a sig.diff.

cold sulphuric acid class AA enamel recipe, but at least 1 x a year

4.5 boiling hydrochloric weight loss: max. 10 g/m /24h (mean value) test duration 48 hours when taking into production a sig.diff.

2

acid resistance enamel recipe, but at least 1x a year

2

4.6 boiling water weight loss: max. 10 g/m /24h (mean value) test duration 48 hours when taking into production a sig.diff.

enamel recipe, but at least 1 x a year

4.9 impact resistance at 20 N no damages when taking into production a sig.diff.

> 2 mm diameter after 24 hours enamel recipe, but at least 1 x a year

© EEA2025 page 88