Page 84 - 20250602 EEA QM Edition 6.0

P. 84

Quality Requirements Edition 6.0 European Enamel Association

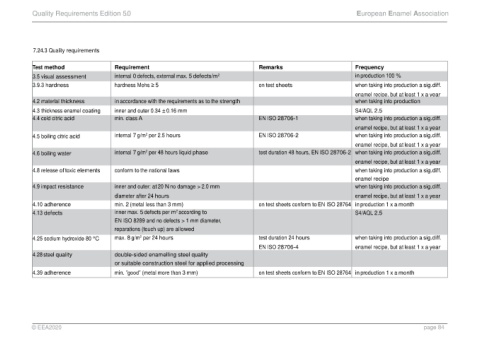

7.22.3 Quality requirements

Test method Requirement Remarks Frequency

3.9 hardness hardness Mohs scale ≥ 4 respecting cutability when taking into production a sig.diff.

enamel recipe, but at least 1 x a year

4.3 thickness enamel coating 200 – 600μm (flat area) the coat thickness depends on S4/AQL 6.5

≥ 150μm (edge covering) the intended use

4.4 cold citric acid class AA each lot

suitable for soil class III soil class III when taking into production a sig.diff.

enamel recipe, but at least 1 x a year

4.6 boiling water no visible change of surface structure, 48 hours water 100°C, steam when taking into production a sig.diff.

loss of gloss is acceptable ≥ 100°C enamel recipe, but at least 1 x a year

4.9 impact resistance at 10 N no damages > 1,5 mm diameter after 24 hours DIN 3475 when taking into production a sig.diff.

enamel recipe, but at least 1 x a year

4.13 surface properties single defect ≤ 1 mm diameter, less than 7 pores visual check without magnification S4/AQL 6.5

within 35 mm circle

4.18 scratch resistance no creeping, no loss of adherence 3 days in distilled water ≥ 80°C when taking into production a sig.diff.

enamel recipe, but at least 1 x a year

4.19 colour difference even and smooth surface small colour differences at edges when taking into production a sig.diff.

are legal enamel recipe, but at least 1 x a year

4.26 abrasion resistance no creeping, no loss of adherence test with 100 N, 60 mm relatively when taking into production a sig.diff.

3 days in distilled water ≥ 80°C enamel recipe, but at least 1 x a year

4.40 thermal shock no visible defect temperature difference = 200°C when taking into production a sig.diff.

enamel recipe, but at least 1 x a year

4.48 mechanical impact no creeping, no loss of adherence 3 days in distilled water ≥ 80°C when taking into production a sig.diff.

resistance enamel recipe, but at least 1 x a year

4.49 weathering & UV no separation, no loss of cycle time 12 hours, 10-50°C, 30- when taking into production a sig.diff.

resistance corrosion resistance, no chalky 75% rel. humidity, afterwards enamel recipe, but at least 1 x a year

change of colour 168 hours UV-radiation 300 W, 0,5 m

then 3 days in distilled water ≥ 80°C

© EEA2025 page 84