Page 86 - 20250602 EEA QM Edition 6.0

P. 86

Quality Requirements Edition 6.0 European Enamel Association

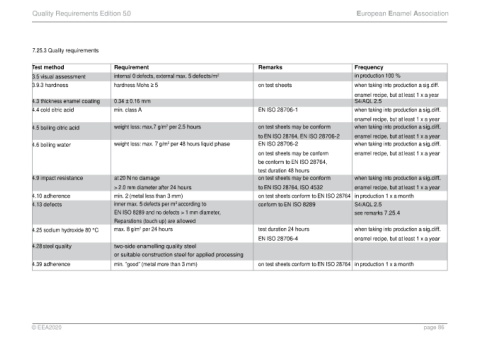

7.23.3 Quality requirements

Test method Requirement Remarks Frequency

4.3 thickness enamel coating 0.8 - 2.5 mm (cast iron) the coating thickness depends of the in consultation between enameller

1.0 - 2.2 mm (steel) enamels used and the intended use and customer

4.25 corrosion rate in sodium ≤ 0.40 mm/a when taking into production a sig.diff.

hydroxide solution enamel recipe, but at least 1 x a year

4.33 corrosion rate in ≤ 0.08 mm/a when taking into production a sig.diff.

hydrochloric acid enamel recipe, but at least 1 x a year

4.34 crack formation ≥ 190 °C when taking into production a sig.diff.

temperature enamel recipe, but at least 1 x a year

© EEA2025 page 86