Page 5 - 20250602 EEA QM Edition 6.0

P. 5

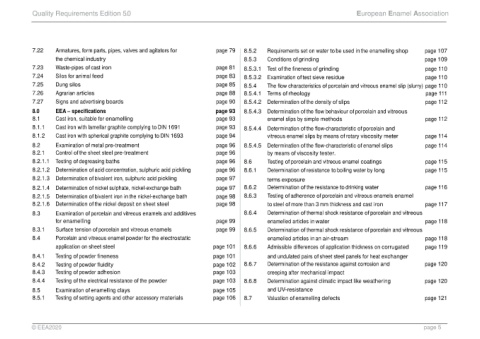

Quality Requirements Edition 6.0 European Enamel Association

7.22 Valves and fittings of cast iron in contact with water page 83 8.5.2 Requirements set on water to be used in the enamelling shop page 110

7.23 Armatures, form parts, pipes, valves and agitators for 8.5.3 Conditions of grinding page 112

for the chemical industry page 85 8.5.3.1 Test of the fineness of grinding page 113

7.24 Waste-pipes of cast iron page 87 8.5.3.2 Examination of test sieve residue page 113

7.25 Agricultural silos page 89 8.5.4 The flow characteristics of porcelain and vitreous enamel slip (slurry) page 113

7.26 Agrarian articles page 91 8.5.4.1 Terms of rheology page 114

7.27 Signs and advertising boards page 93 8.5.4.2 Determination of the density of slips page 115

8.0 EEA – specifications page 96 8.5.4.3 Determination of the flow behaviour of porcelain and vitreous

8.1 Cast iron, suitable for enamelling page 96 enamel slips by simple methods page 115

8.1.1 Cast iron with lamellar graphite complying to DIN 1691 page 96 8.5.4.4 Determination of the flow-characteristic of porcelain and

8.1.2 Cast iron with spherical graphite complying to DIN 1693 page 97 vitreous enamel slips by means of rotary viscosity meter page 117

8.2 Examination of metal pre-treatment page 99 8.5.4.5 Determination of the flow-characteristic of enamel slips

8.2.1 Control of the sheet steel pre-treatment page 99 by means of viscosity tester. page 117

8.2.1.1 Testing of degreasing baths page 99 8.6 Testing of porcelain and vitreous enamel coatings page 118

8.2.1.2 Determination of acid concentration, sulphuric acid pickling page 99 8.6.1 Determination of resistance to boiling water by long

8.2.1.3 Determination of bivalent iron, sulphuric acid pickling page 100 terms exposure page 118

8.2.1.4 Determination of nickel sulphate, nickel-exchange bath page 100 8.6.2 Determination of the resistance to drinking water page 119

8.2.1.5 Determination of bivalent iron in the nickel-exchange bath page 101 8.6.3 Testing of adherence of porcelain and vitreous enamels enamel

8.2.1.6 Determination of the nickel deposit on sheet steel page 101 to steel of more than 3 mm thickness and cast iron page 120

8.3 Examination of porcelain and vitreous enamels and additives 8.6.4 Determination of thermal shock resistance of porcelain and vitreous

for enamelling page 102 enamelled articles in water page 121

8.3.1 Surface tension of porcelain and vitreous enamels page 102 8.6.5 Determination of thermal shock resistance of porcelain and vitreous

8.4 Porcelain and vitreous enamel powder for the electrostatic enamelled articles in an air-stream page 121

application on sheet steel page 104 8.6.6 Admissible differences of application thickness on corrugated

8.4.1 Testing of powder fineness page 104 and undulated pairs of sheet steel panels for heat exchanger page 122

8.4.2 Testing of powder fluidity page 105 8.6.7 Determination of the resistance against corrosion and

8.4.3 Testing of powder adhesion page 106 creeping after mechanical impact page 123

8.4.4 Testing of the electrical resistance of the powder page 106 8.6.8 Determination against climatic impact like weathering

8.5 Examination of enamelling clays page 108 and UV-resistance page 123

8.5.1 Testing of setting agents and other accessory materials page 109 8.7 Valuation of enamelling defects page 124

© EEA2025 page 5