Page 3 - 20250602 EEA QM Edition 6.0

P. 3

Quality Requirements Edition 6.0 European Enamel Association

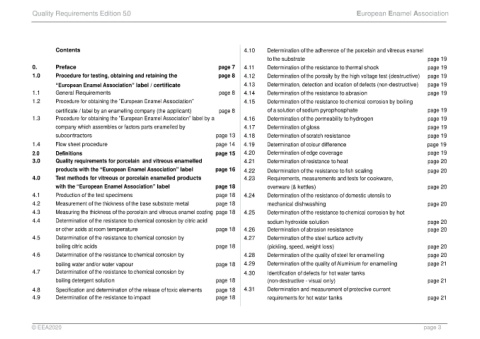

Contents 4.10 Determination of the adherence of the porcelain and vitreous enamel

to the substrate page 19

0. Preface page 7 4.11 Determination of the resistance to thermal shock page 19

1.0 Procedure for testing, obtaining and retaining the 4.12 Determination of the porosity by the high voltage test page 19

“European Enamel Association” certificate page 8 4.13 Determination, detection and location of defects (non-destructive) page 19

1.1 General page 8 4.14 Determination of the resistance to abrasion page 19

1.2 Procedure for obtaining the “European Enamel Association” 4.15 Determination of the resistance to chemical corrosion by boiling

certificate by an enamelling company (the applicant) page 9 of a solution of sodium pyrophosphate page 19

1.3 Procedure for obtaining the “European Enamel Association” 4.16 Determination of the permeability to hydrogen page 19

certificate by a company which assembles or factors 4.17 Determination of gloss page 19

parts enamelled by subcontractors page 13 4.18 Determination of scratch resistance page 19

1.4 Flow sheet procedure page 14 4.19 Determination of colour difference page 19

2.0 Definitions page 15 4.20 Determination of edge coverage page 19

3.0 Quality requirements for “European Enamel Association” 4.21 Determination of resistance to heat page 20

certified products page 16 4.22 Determination of the resistance to fish scaling page 20

4.0 Test methods for vitreous or porcelain enamelled 4.23 Requirements, measurements and tests for cookware,

certified products page 18 ovenware (& kettles) page 20

4.1 Production of the test specimens page 18 4.24 Determination of the resistance of domestic utensils to

4.2 Measurement of the thickness of the base substrate metal page 18 mechanical dishwashing page 20

4.3 Measuring the thickness of the porcelain and vitreous enamel 4.25 Determination of the resistance to chemical corrosion by hot

coating page 18 sodium hydroxide solution page 20

4.4 Determination of the resistance to chemical corrosion by citric acid 4.26 Determination of abrasion resistance page 20

or other acids at room temperature page 18 4.27 Determination of the steel surface activity

4.5 Determination of the resistance to chemical corrosion by (pickling, speed, weight loss) page 20

boiling citric acids page 18 4.28 Determination of the quality of steel for enamelling page 20

4.6 Determination of the resistance to chemical corrosion by 4.29 Determination of the quality of Aluminium for enamelling page 21

boiling water and/or water vapour page 18 4.30 Identification of defects for hot water tanks

4.7 Determination of the resistance to chemical corrosion by (non-destructive - visual only) page 21

boiling detergent solution page 18 4.31 Determination and measurement of protective current

4.8 Specification and determination of the release of toxic elements page 18 requirements for hot water tanks page 21

4.9 Determination of the resistance to impact page 18

© EEA2025 page 3