Page 4 - 20250602 EEA QM Edition 6.0

P. 4

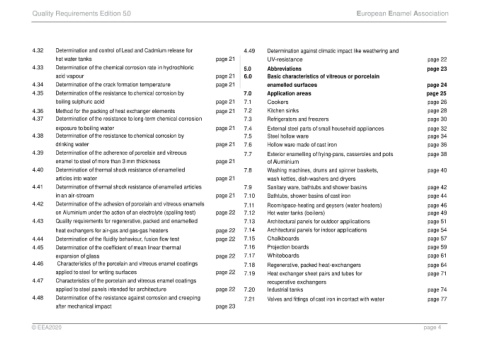

Quality Requirements Edition 6.0 European Enamel Association

4.32 Determination and control of release of elements for 4.49 Determination against climatic impact like weathering and

hot water tanks page 21 UV-resistance page 22

4.33 Determination of the chemical corrosion rate in hydrochloric 5.0 Abbreviations page 23

acid vapour page 21 6.0 Basic characteristics of vitreous or porcelain

4.34 Determination of the crack formation temperature page 21 enamelled surfaces page 24

4.35 Determination of the resistance to chemical corrosion by 7.0 Application areas page 25

boiling sulphuric acid page 21 7.1 Cookers page 26

4.36 Method for the packing of heat exchanger elements page 21 7.2 Kitchen sinks page 28

4.37 Determination of the resistance to long-term chemical corrosion 7.3 Refrigerators and freezers page 30

exposure to boiling water page 21 7.4 External steel parts of small household appliances page 32

4.38 Determination of the resistance to chemical corrosion by 7.5 Steel holloware page 34

drinking water page 21 7.6 Holloware made of cast iron page 36

4.39 Determination of the adherence of porcelain and vitreous 7.7 Exterior enamelling of frying-pans, casseroles and pots

enamel to steel of more than 3 mm thickness page 21 of Aluminium page 38

4.40 Determination of thermal shock resistance of enamelled 7.8 Washing machines, drums and spinner baskets,

articles into water page 21 wash kettles, dish-washers and dryers page 40

4.41 Determination of thermal shock resistance of enamelled articles 7.9 Sanitary ware, bathtubs and shower basins page 42

in an air-stream page 21 7.10 Bathtubs, shower basins of cast iron page 44

4.42 Determination of the adhesion of porcelain and vitreous enamels 7.11 Room/space-heating and geysers (water heaters) page 46

on Aluminium under the action of an electrolyte (spalling test) page 22 7.12 Hot water tanks (boilers) page 49

4.43 Quality requirements for regenerative, packed and enamelled 7.13 Architectural panels for outdoor applications page 51

heat exchangers for air-gas and gas-gas heaters page 22 7.14 Architectural panels for indoor applications page 54

4.44 Determination of the fluidity behaviour, fusion flow test page 22 7.15 Chalkboards page 57

4.45 Determination of the coefficient of mean linear thermal 7.16 Projection boards page 59

expansion of glass page 22 7.17 Whiteboards page 61

4.46 Characteristics of the porcelain and vitreous enamel coatings 7.18 Regenerative, packed heat-exchangers page 64

applied to steel for writing surfaces page 22 7.19 Heat exchanger sheet pairs and tubes for

4.47 Characteristics of the porcelain and vitreous enamel coatings recuperative exchangers page 71

applied to steel panels intended for architecture page 22 7.20 Industrial tanks 1 GROUP page 74

st

4.48 Determination of the resistance against corrosion and creeping 7.21 Industrial tanks 2 GROUP page 79

nd

after mechanical impact page 22

© EEA2025 page 4