Page 105 - 20250602 EEA QM Edition 6.0

P. 105

Quality Requirements Edition 6.0 European Enamel Association

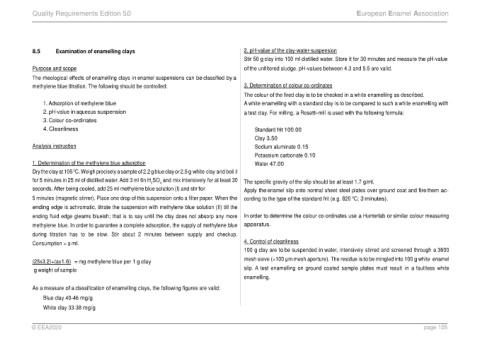

8.4.2 Testing of powder fluidity Fluidity meter (sketch)

The fluidity of a powder means the ability to get whirled up in a gas stream. This

A – air flow regulation unit

property is essential for how the powder can be transported through the tubes and

B – control panel

pipes of a powder installation. Also, the output of the spray guns is depending on it.

C – fluidizing cylinder with

The fluidity can be measured by the SAMES fluidity meter type AS100 or

perforated bottom

comparable.

D – weighing container

E – inlet pressurized air

In order to get reproducible results, the following parameters are essential: F – fine regulator air flow

G – coarse regulator air flow

a. the regularity of the powder H – switch button

b. the temperature and humidity of the air stream I – graduated air flow meter

J – pressure indication

c. the velocity of the air stream

K – powder outlet

d. the geometry of the fluidizing bottom and the powder outlet

Test procedure:

250 g of powder is filled into the cylinder C with perforated bottom (see fig.). The

powder is to be fluidized with a well-defined air stream (rel. humidity < 5 % C, temp.

25 °C, airflow ca. 200 N1/h) and additionally stirred with a spatula for one minute.

After the fluidized powder has reached a maximum volume in the cylinder, the outlet

K is opened and the powder trickling out in a container D during 30 seconds is then

weighed. The average value in gram can be used as a direct indication for fluidity of

the powder which will be expressed as gram/30 s. Quite generally a minimum fluidity

of 70 g/30 swill be required, the individual values being dependent on the specific

conditions in the powder booth.

© EEA2025 page 105