Page 104 - 20250602 EEA QM Edition 6.0

P. 104

Quality Requirements Edition 6.0 European Enamel Association

8.4 Enamel powder for the electrostatic application on sheet steel 8.4.1 Testing of powder fineness

The parameters of a powder affecting its workability in the enamel shop are The particle size distribution and especially the share of grains > 60μm in powder

residue of powder, fluidity, electrical resistance as well as adherence of the powder enamels affects the application properties in the enamelling shop. It can be determined

on the sheet steel after electrostatic application. They are to be registered in the by the known PEMCO test sieve (screen aperture 0.06 mm = 60μm = 10000

laboratory and to be reproduced within quantitatively acceptable limits. mesh/cm ).

2

The following standard data have proved to be characteristic for an electrostatic The residue of the powder in percentage by weight is a measure for the frequency of the

powder: particles > 60μm.

- Residue of powder RP > 40μm in % The figures can be reproduced up to an exactness of ± 0.5%. With laser or XRF-

- Fluidity of powder FP in g/s methods – also used for the production control of powder enamels – a complete

- Short time powder adherence STPA in % granulometric analysis including statistical information (d50, standard deviation) can be

obtained.

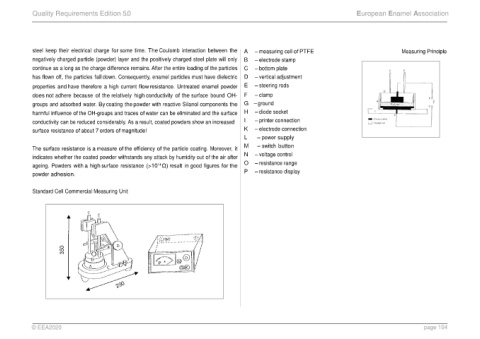

- Surface resistance of powder SRP in Ω cm

(the resistivity is mostly determined in Ω cm)

From instrumental and external influences cleared measuring data is condition of a

basic research in the field of electrostatic powder application as well as quality control

in the plant and information concerning the powder behaviour in the enamel shop.

© EEA2025 page 104