Page 41 - 20250602 EEA QM Edition 6.0

P. 41

Quality Requirements Edition 6.0 European Enamel Association

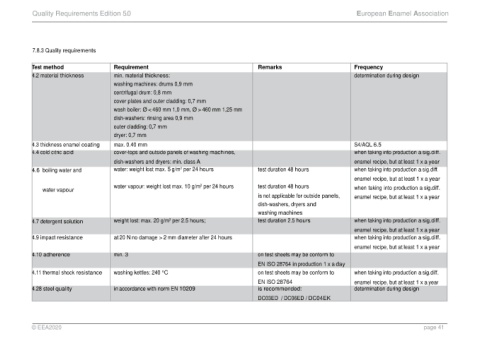

7.8.3 Quality requirements

Test method Requirement Remarks Frequency

4.2 material thickness min. material thickness: determination during design

washing machines: drums 0,9 mm and centrifugal drum:

0,8 mm

cover plates and outer cladding: 0,7 mm

wash boiler: Ø < 460 mm 1,0 mm, Ø > 460 mm 1,25 mm

dish-washers: rinsing area 0,9 mm

outer cladding: 0,7 mm

dryer: 0,7 mm

4.3 thickness enamel coating max. 0.40 mm S4/AQL 6.5

4.4 cold citric acid cover-tops and outside panels of washing machines, when taking into production a sig.diff.

dish-washers and dryers: min. class A enamel recipe, but at least 1 x a year

2

4.6 boiling water and water water: weight lost max. 5 g/m /24h (mean value) test duration 48 hours when taking into production a sig.diff.

vapour enamel recipe, but at least 1 x a year

water vapour: weight lost max. 10 g/m /24h (mean value) test duration 48 hours

2

is not applicable for outside panels,

dish-washers, dryers and washing

machines

4.7 detergent solution weight loss: max. 20 g/m per 2.5 hours; test duration 2.5 hours when taking into production a sig.diff.

2

enamel recipe, but at least 1 x a year

4.9 impact resistance at 20 N no damage > 2 mm diameter after 24 hours when taking into production a sig.diff.

enamel recipe, but at least 1 x a year

4.10 adherence min. 3 on test sheets conform to in production 1 x a day

EN ISO 28764

4.11 thermal shock resistance washing kettles: 240 °C on test sheets conform to EN ISO 28764 when taking into production a sig.diff.

enamel recipe, but at least 1 x a year

4.19 colour difference even and smooth surface, evaluated equal to the appearance Colour difference possibly measured with In production 100%

of an approved enamelled sample a spectrometer and tolerances previously

agreed by interested partners

4.28 steel quality in accordance with norm EN 10209 is recommended: determination during design

DC03ED / DC06ED / DC04EK

© EEA2025 page 41