Page 35 - 20250602 EEA QM Edition 6.0

P. 35

Quality Requirements Edition 6.0 European Enamel Association

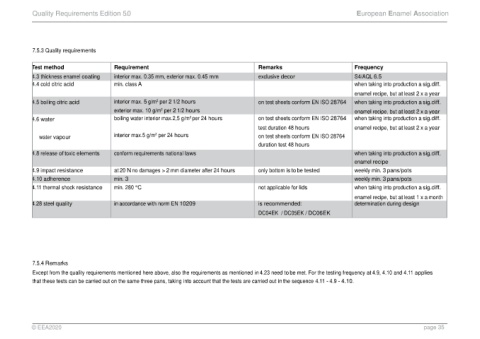

7.5.3 Quality requirements

Test method Requirement Remarks Frequency

4.3 thickness enamel coating interior max. 0.35 mm, exterior max. 0.45 mm excluding decor S4/AQL 6.5

4.4 cold citric acid min. class A when taking into production a sig.diff.

enamel recipe, but at least 2 x a year

4.5 boiling citric acid interior max. 5 g/m per 2 1/2 hours on test sheets conform EN ISO 28764 when taking into production a sig.diff.

2

2

exterior max. 10 g/m per 2 1/2 hours enamel recipe, but at least 2 x a year

4.6 water boiling water interior max. 2,5 g/m²/24h (mean value) on test sheets conform EN ISO 28764 when taking into production a sig.diff.

test duration 48 hours enamel recipe, but at least 2 x a year

water vapour interior max.5 g/m /24 hours (mean value) on test sheets conform EN ISO 28764

2

duration test 48 hours

4.8 release of toxic elements conform to requirements of national laws when taking into production a sig.diff.

enamel recipe and following

requirements of proper and safe

surveillance plan

4.9 impact resistance at 20 N no damages > 2 mm diameter after 24 hours only bottom is to be tested weekly min. 3 pans/pots

4.10 adherence min. 3 weekly min. 3 pans/pots

4.11 thermal shock resistance min. 280 °C not applicable for lids when taking into production a sig.diff.

enamel recipe, but at least 1 x a month

4.19 colour difference even and smooth surface, evaluated equal to the Colour difference possibly measured with a In production 100%

appearance of an approved enamelled sample spectrometer and tolerances previously agreed

by interested partners

4.28 steel quality in accordance with norm EN 10209 is recommended: determination during design

DC04EK /DC05EK / DC06EK / DC07EK

7.5.4 Remark

On top of the quality requirements mentioned here above, also the requirements as mentioned in 4.23 need to be met.

For the testing frequency at 4.23, 4.9, 4.10 and 4.11, tests can be carried out on the same three products, taking into account a logical sequence 4.23 - 4.11 - 4.9 then 4.10.

© EEA2025 page 35