Page 20 - 20250602 EEA QM Edition 6.0

P. 20

Quality Requirements Edition 6.0 European Enamel Association

4.21 Determination of resistance to heat 4.26 Determination of abrasion resistance

Determination of the resistance to heat should be carried out using the methods as The determination of the abrasion resistance should be carried out using the methods

specified in EN ISO 4530. as specified in ASTM C501. For some applications EN ISO 6370-1 and -2 can be

used.

4.22 Determination of the resistance to fish scaling

The determination of the resistance to fishscale should be carried out using the 4.27 Determination of the steel surface activity (pickling speed, weight loss)

methods as specified in EN 10209 Annex A2, by which the test sheet (150 mm x coil The determination of the steel surface activity should be carried out using the methods

width) is pre- treated without nickel. The front and back sides are enamelled with a as specified in EN 10209: Annex B.

fishscale sensitive porcelain and vitreous enamel supplied by the several

manufacturers of enamel/frit. Coating thickness, firing temperature, firing time and

potential thermal treatment shall be specified by the frit supplier. See part 4.4 of EN 4.28 Determination of the quality of steel for enamelling

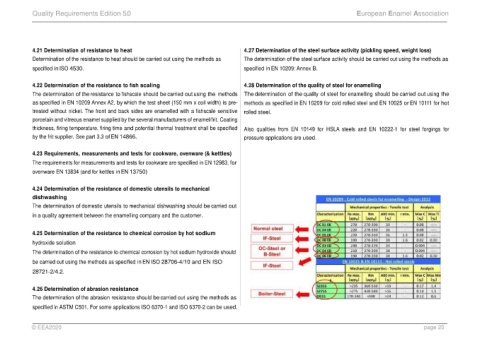

ISO 28763. Qualities of cold rolled steels for enamelling are specified in EN 10209.

4.23 Requirements, measurements and tests for cookware, ovenware EN 10025 or EN 10111 are classifying hot rolled steel qualities, but do not mention any

(& kettles) specific performance related to enamelling.

The requirements for measurements and tests for cookware are specified in EN Enamelling with hot rolled steels is not guaranteed, any quality can be used, but here

12983, for ovenware EN 13834 (and for kettles in EN 13750) are some recommendations:

DD11 or DD12 & DD13 (as defined in EN10111) can result in inconsistent mechanical

4.24 Determination of the resistance of domestic utensils to mechanical properties and fatigue resistance (cyclic pressure tests) after enamelling.

dishwashing References S235 JR, S275 JR, S355 MC or S240EK & S300EK (those two are not

official references and proposed only by few steel providers) are preferred.

The determination of domestic utensils to mechanical dishwashing should be carried

out in a quality agreement between the enamelling company and the customer.

Also, qualities from EN 10149 for HSLA steels and EN 10222-1 for steel forgings for

pressure applications are used.

4.25 Determination of the resistance to chemical corrosion by hot sodium

hydroxide solution

The determination of the resistance to chemical corrosion by hot sodium hydroxide

should be carried out using the methods as specified in EN ISO 28706-4/10 and EN

ISO 28721-2/4.2.

© EEA2025 page 20