Page 47 - 20250602 EEA QM Edition 6.0

P. 47

Quality Requirements Edition 6.0 European Enamel Association

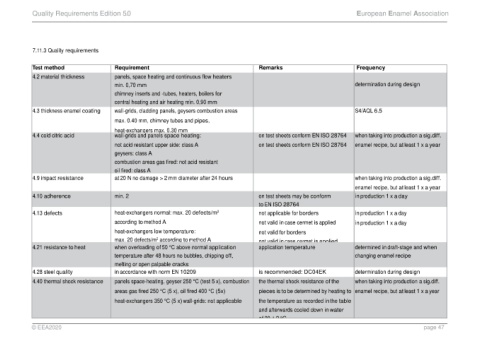

7.11.3 Quality requirements

Test method Requirement Remarks Frequency

4.2 material thickness panels, space heating and continuous flow heaters determination during design

min. 0,70 mm

chimney inserts and -tubes, heaters, boilers for

central heating and air heating min. 0,90 mm

4.3 thickness enamel coating wall-grids, cladding panels, geysers combustion areas S4/AQL 6.5

max. 0.40 mm

chimney tubes and pipes, heat-exchangers max. 0.30 mm

4.4 cold citric acid wall-grids and panels space heating: no acid resistance on test sheets conform EN ISO 28764 when taking into production a sig.diff.

upper side: class A enamel recipe, but at least 1 x a year

geysers: class A

combustion areas:

gas fired: no acid resistance

oil fired: class A

4.9 impact resistance at 20 N no damage > 2 mm diameter after 24 hours when taking into production a sig.diff.

enamel recipe, but at least 1 x a year

4.10 adherence min. 2 on test sheets conform to EN ISO 28764 in production 1 x a day

4.13 defects Normal heat-exchangers: not applicable for borders in production 1 x a day

2

max. 20 defects/m according to method A not valid in case cermet is applied

Low temperature heat-exchangers: not valid for borders in production 1 x a day

max. 20 defects/m according to method A not valid in case cermet is applied

2

4.21 resistance to heat when overloading of 50 °C above normal application application temperature determined in draft-stage and when

temperature after 48 hours no bubbles, chipping off, changing enamel recipe

melting or open palpable cracks

4.28 steel quality in accordance with norm EN 10209 is recommended: DC04EK determination during design

4.40 thermal shock resistance panels space-heating, geyser 250 °C (test 5 x), the thermal shock resistance of the pieces when taking into production a sig.diff.

combustion areas gas fired 250 °C (5 x), is to be determined by heating to the enamel recipe, but at least 1 x a year

oil fired 400 °C (5x), temperature as recorded in the table and

heat-exchangers 350 °C (5 x), afterwards cooled down in water

wall-grids: not applicable of 20 ± 2 °C

© EEA2025 page 47