Page 27 - 20250602 EEA QM Edition 6.0

P. 27

Quality Requirements Edition 6.0 European Enamel Association

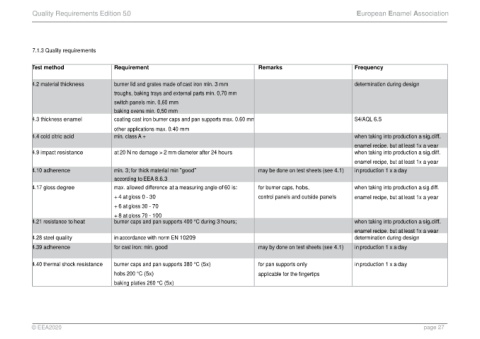

7.1.3 Quality requirements

Test method Requirement Remarks Frequency

4.2 material thickness burner lid and grates made of cast iron min. 3 mm determination during design

troughs, baking trays and external parts min. 0,70 mm

switch panels min. 0,60 mm

baking ovens min. 0,50 mm

4.3 thickness enamel coating cast iron burner caps and pan supports max.0.60mm S4/AQL 6.5

other applications max. 0.40 mm

4.4 cold citric acid min. class A + when taking into production a sig.diff.

enamel recipe, but at least 1x a year

4.9 impact resistance at 20 N no damage > 2 mm in diameter after 24 hours when taking into production a sig.diff.

enamel recipe, but at least 1x a year

4.10 adherence min. 3; for thick material min. “good” possibly done on test sheets (see 4.1) in production 1 x a day

according to EEA 8.6.3

4.17 determination of gloss max. allowed difference at a measuring angle of 60 is: for burner caps, hobs, when taking into production a sig.diff.

+ 4 at gloss 0 - 30 control panels and outside panels enamel recipe, but at least 1x a year

+ 6 at gloss 30 - 70

+ 8 at gloss 70 - 100

4.19 colour difference even and smooth surface, evaluated equal to the appearance colour difference possibly measured with in production 100%

of an approved enamelled sample a spectrometer and tolerances

previously agreed by interested partners

4.21 resistance to heat burner caps and pan supports: 400 °C during 3 hours when taking into production a sig.diff.

enamel recipe, but at least 1x a year

4.28 steel quality in accordance with norm EN 10209 determination during design

4.39 adherence for cast iron: min. good possibly done on test sheets (see 4.1) in production 1 x a day

4.40 thermal shock resistance burner caps and pan supports: 380 °C (5x) for pan supports, only applicable in production 1 x a day

hobs: 200 °C (5x) for the fingertips

baking platies: 260 °C (5x)

© EEA2025 page 27